My wife's grandfather owned a drill press vice that she ultimately inherited from her father.

-

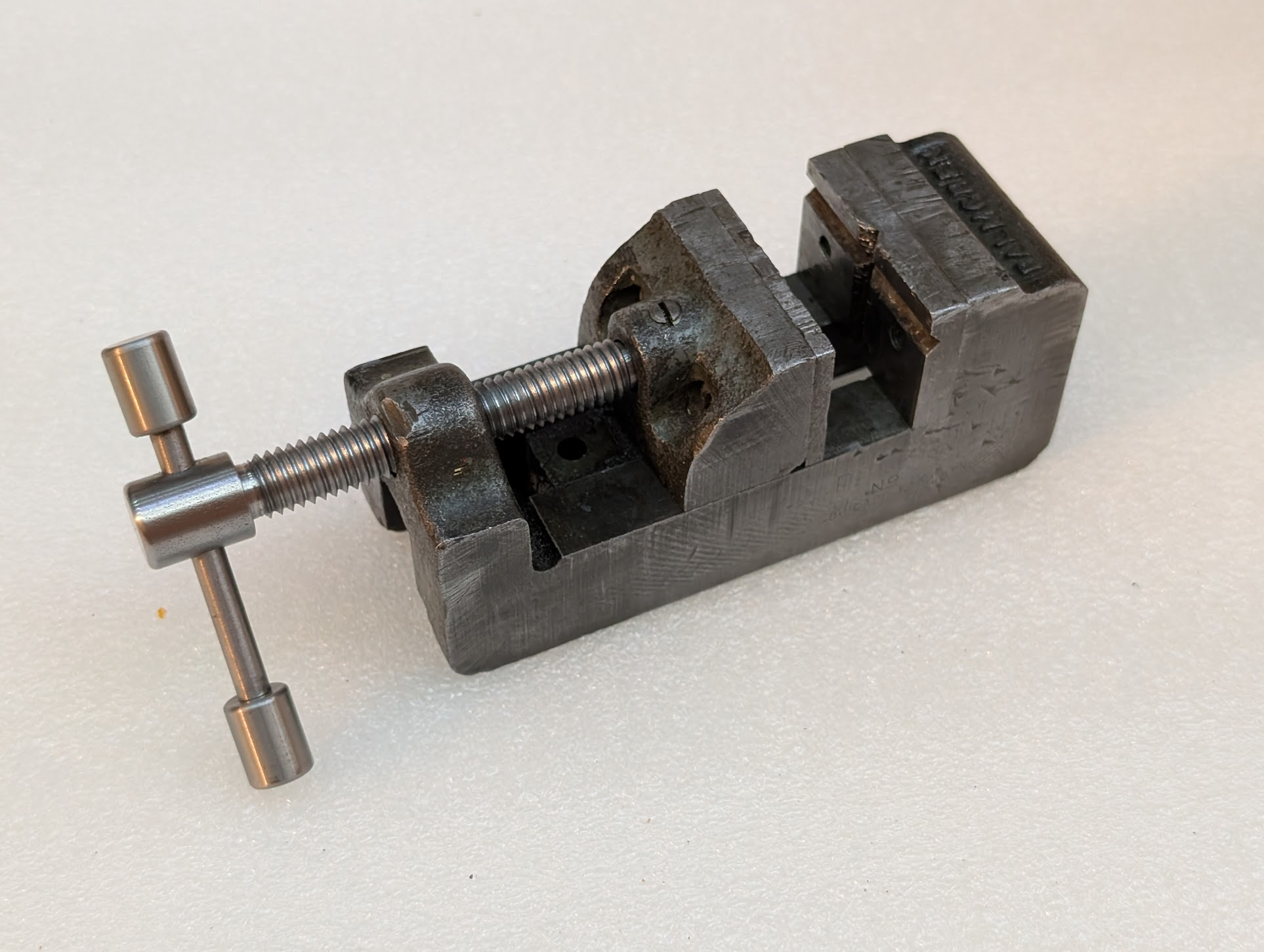

My wife's grandfather owned a drill press vice that she ultimately inherited from her father. It had lost its handle, and the threads on the handle end of the lead screw were chowdered from someone using vice grips on them. It was missing a jaw screw and had the wrong screws in the moveable jaw plate.

But none of the damage was critical. The lead screw needed to be replaced (a simple lathe job), and screws replaced —but the slide ways are smooth and not corroded, and it seems very square (though I haven't measured that yet). This tool has good bones.

As I'm finishing making a new (better!) lead screw, it occurred to me that I should search to see if I could find images of the handle to help me make it look vaguely original.

Reader, this vice is still sold new today. $118 (plus shipping and tax yada yada) makes me realize that I'm investing in restoring a quality tool to function, not just restoring an item of purely sentimental value.

-

G gustavinobevilacqua@mastodon.cisti.org shared this topic on

G gustavinobevilacqua@mastodon.cisti.org shared this topic on

-

The shiny parts are new. The jaws need to be replaced but I don't have any flat ground stock to make them from. It's usable now for most purposes,

There were several dings and nicks, and I stoned them out to improve flatness of the reference surfaces.

This picture does not show the two new #12-24 x 7/16" screws underneath holding the retaining plate to the movable jaw, and one new #8-32 x 5/8" Phillips fillister head machine screw holding the grooved plate to the fixed jaw.

In related news, I have 99 #8-32 x 5/8" Phillips fillister head machine screws that I have no use for, because I normally run a metric shop.

The side says "PALMGREN No 6 CHICAGO TOOL PNG CC" as far as I can tell, but you can't read it in this picture.

The lead screw is made from 1/2" 1144 stressproof, with a handle made from 3/16" O1 (it's precision ground for a smooth fit in a reamed hole) and handle ends made from 3/8" O1 (it's what I had handy in 3/8"). The handle ends are held on with retaining compound.

-

@mcdanlj Very cool. I also have a drill press vise I inherited, which has ears for clamping. Can't see a manufacturer label. Meanwhile I found a modern combo with ViseGrip style.