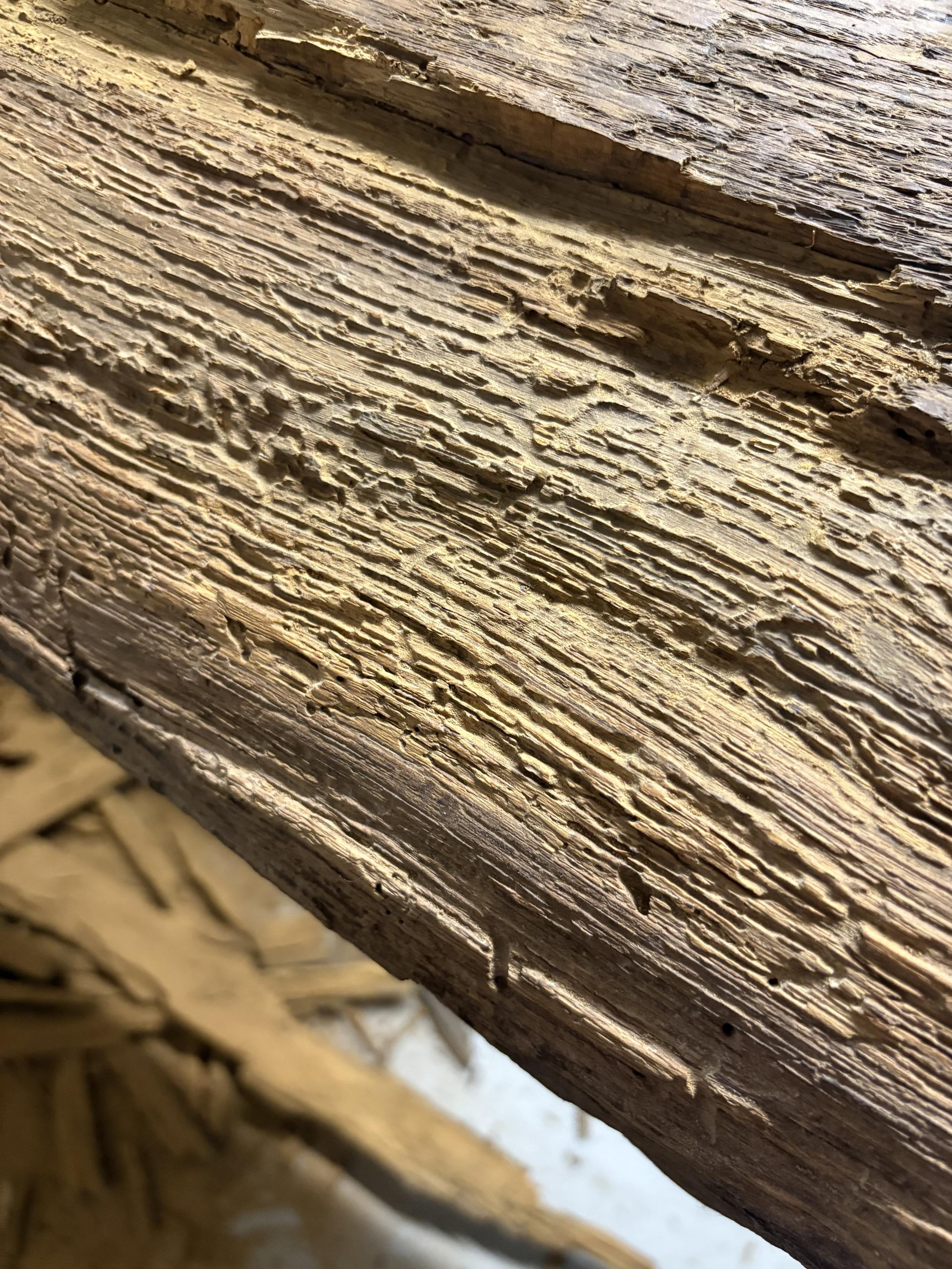

I think I’ve mentioned before that the stairs post had a bit of worm sign in the top region and it was undoubtedly kept as part of the charm.

-

I think I’ve mentioned before that the stairs post had a bit of worm sign in the top region and it was undoubtedly kept as part of the charm.

But when tapping around the area, you could tell the integrity was bad in the surface rings. I decided to remove all rotted material and get it down to the solid worm texturing, which I will keep.

Glad I did. The extent of worm powder was considerable under the surface.

-

G gustavinobevilacqua@mastodon.cisti.org shared this topic

G gustavinobevilacqua@mastodon.cisti.org shared this topic

-

It pays to do to the actual measuring, which I’ve done here now to scale. 1 square = 5 cm.

Not enough room for what I was thinking before, but I’ll get spiraling in on bottom half.

I’ve sketched the four sides. Blank areas are hewn post surface. Flowing dotted pattern is exposed worm texturing under removed rotted surface (now solid). And you can see three big mortises, and where a triangular chunk broke off bottom. The back has many 2-penny nails broke off at surface (dots).

Cont.

-

Post is going on slimfast plan. I was going to avoid it, but I need this side more square than it was for positioning reasons later. It shallows as it goes until by that third mortise nothing more is coming off.

This will make spiraling easier, too.

There are a lot of hidden nails, so using the crappiest saw, which actually works well.

-

This chisel is one of my biggest. I wish I had a slick, but this is getting it done.

I put an edge on it, but it’s not restored yet, obviously. Big round bolster. I love it.

Those steel pipe ferrules have 3mm walls.

-

Fat has been trimmed. The wood is quite nice under the 200+ years of weathering.

-

The (final) goal:

Where original blind mortises were, I’m making them through, and cutting two more in perpendicular direction, crating a hollowed out crisscross. Where the piece of wood sits will be a third crisscross.

From bottom crisscross to bottom end will be a curved taper to an 11cm footprint. Dramatic! It transitions to worm texturing and grain contours above crisscrosses. May blend into that with shaping yet to determine, a small floating lamp shelf, or both.

-

Two sets of criss-cross mortises done. One more to go.

I put an angle on that one top mortise to follow the grain line a bit. I’m starting to imagine the flowing carved lines now.

Nice thing about these mortises is they don’t have to be perfect or align at all, and they don’t. :) Not really mortises anymore in fact. More like latticing, or something.

I decided I’ll surface everything down to clean, beautiful grain. I can’t wait to start shaping everything.

It’s getting exciting. :)

-

I wish I had a local blacksmith friend who liked doing arty stuff.

NellytheWillow just shared this photo. I was thinking, ‘wow, I’d like to have a window like that.’ Then, it occurred to me how cool it would look to have small grills like that fitting into the big mortises in the post.

Oh well. Nice thing, though, is I can always come back to that idea later.

I wonder what I could do with copper and brass plates, maybe.

Or colored glass.

With a light inside.

-

Speaking of lights inside wood, this brass-button touch-light system is rad.

That would work perfectly for something like the post concept. And I’m eager to work on a lamp.

I’m not saying I’m going down that road here (boss is pushin’ for delivery), but the eyebrows are raising. It’s looking feasible.

There’s a low outlet, too, right where the post will stand, if needed.

-

Thinking on it more, I could probably make mortise grills like those in that window easy enough, but single frame only with the cross and half-rounds. Not the repeating pattern. I would still need an anvil and a welder. I’ve been wanting both.

Bah. Too much detour right now.

But the idea seeds are sprouting

-

First of last four bored.

Remembered I have *one* hex auger, a Ø 18mm. It clears the wide beam from a single side. I could power through with the new Metabo grande. It would take more holes per mortise, but I'd have been done by now.

I’ve gone this far. I’ll keep on by brace.

Can’t use power tools on Sunday anyway.

Can’t use power tools on Sunday anyway.The brace is pleasantly quiet. I like that. Just a soft curling noise as the wood ringlets flow up and over. I usually have to pause once mid hole. It gets the heart rate up.

-

Some wax on the auger could be helpful.

-

Good thought. I need to get some paraffin, in fact. Don’t like using my beeswax stash for such.

-

-

@wedge I've been known to use a bit of bar soap. Though sometimes it is more reactive than paraffin. @GustavinoBevilacqua